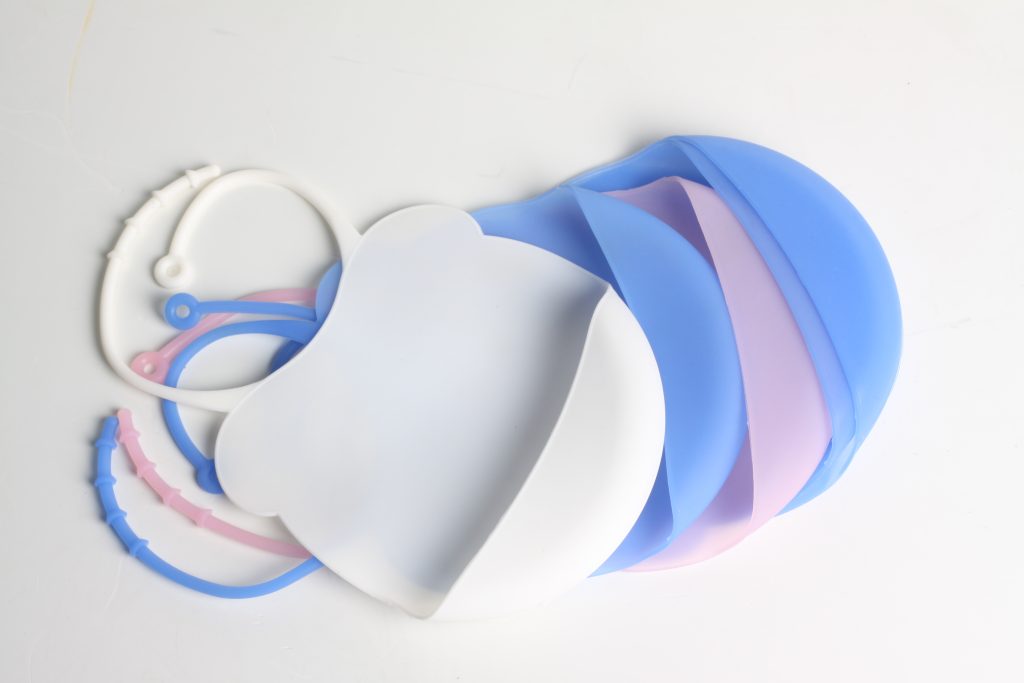

Food grade gaskets

Designer-Manufacturer-Distributor

Food Grade (FDA Approved) Rubber Products for the Food Processing Industry

ANGOF specializes in precision die-cut, rubber molded and extruded Food Grade (FDA) rubber products, including FDA Approved Gaskets and Seals that are used in the Food Processing Industry.

FDA-approved, food-grade rubber products are commonly used in applications where food or consumables are present, such as food processing, beverage bottling and manufacturing, dairy production, meat packing, and pharmaceutical applications. FDA rubber products are also found within most food packaging equipment, such as table-top packaging machinery. All FDA-approved products are handled and packaged in a Class 100 cleanroom environment and subjected to rigorous testing to meet the demands of challenging food and beverage applications.

At ANGOF, our FDA-compliant rubber products are fabricated for your unique application and specifically engineered to handle a wide range of food products, as well as liquid products such as beer, wine, filtered water, and milk. ANGOF takes pride in its ability to consistently produce high-quality, FDA-compliant rubber products guaranteed to meet your exact specifications and function perfectly within your application. If you do not have a blueprint or technical drawing, ANGOF has the ability to reverse engineer solutions for you directly from a sample.

With years of expertise manufacturing custom solutions for various industries,ANGOF is an ideal provider for high-quality, food-grade rubber gaskets and seals. We can fully customize your gaskets and cut them to any size.

This material selection guide will provide an overview of FDA standards for food-grade materials and some of the typical applications for each material, helping you to identify the ideal food-grade gasket or seal for your application.

Food-Grade Gaskets and Seals 101

Finding the ideal food-grade gasket or seal material can be vital to an application. It requires a basic understanding of requirements for FDA approval, along with the material properties that best suit the specifics of your use case. Food-grade materials must be hypoallergenic, non-toxic, flexible, tasteless, odorless. They should also prohibit bacterial growth and have a wide operating temperature range.

ANGOF provides an array of food-grade (FDA-approved) custom rubber products, including:

- Food-grade/FDA-compliant gaskets and seals

- FDA dust covers

- FDA suction cups

- FDA rubber shields

- FDA flexible rubber couplings

- High-purity gaskets and seals

- Sanitary gaskets and seals

Meeting FDA Standards for Food Processing Applications

Gaskets and seals for food processing applications are required to meet FDA standards. The Code of Federal Regulations, Title 21, Chapter 1, Part 177 identifies eligible polymers for constructing food-grade gaskets and seals. Gaskets must be made from approved materials and undergo testing before receiving FDA approval.

Compounds used in food processing are referred to as food contact substances (FCS). These compounds consist of several additives that may each be FDA-approved, but as a whole will not receive approval until the FDA evaluates the allowable extraction limits. Compounds used to make food-grade gaskets include numerous elastomers, Viton®, and PTFE.

FDA Gasket Materials – Types, Properties, and Applications

ANGOF offers numerous rubber materials and compounds that meet FDA requirements and NSF regulations for food processing applications, including FDA Silicone, FDA Nitrile (Buna-N, NBR), FDA EPDM, and FDA Neoprene. These rubber polymers exhibit natural resistance to bacteria build-up, a broad range of working temperatures, excellent resistance to chemical properties, good flexibility, and possess odorless and tasteless properties.

FDA Silicone Rubber

FDA silicone rubber products can be provided in a variety of configurations to suit your particular application. All our food-grade silicone products are FDA-compliant and can provide reliable service at temperatures ranging from -67°F to 450°F. FDA silicone is typically red, white, gray, or translucent in color. It is an ideal material for high-heat applications, such as sealing oven doors. Silicone’s UV- and ozone-resistance also make it a preferred material for gaskets on barbeque grills and commercial vent hoods.

FDA Nitrile (Buna-N) Rubber

FDA nitrile rubber is sturdy enough to handle suction and discharge for food and dairy products. It withstands temperatures of -40°F to 212°F and is known for its high resistance to animal fat and vegetable oils. FDA nitrile is usually black or white in color. Its abrasion-resistance makes it a preferred material for wear-prone applications, such as jar lid seals, pharmaceutical and food handling chutes, and food processing conveyors.

FDA EPDM Rubber

FDA ethylene propylene diene monomer (EPDM) rubber is used in applications that demand both flexibility and ruggedness. This material is made from odorless and tasteless compounds and can be used in applications involving the transfer of oily substances. FDA EPDM products are ideal for food and beverage, dairy, and other relevant applications within the temperature range of -40°F to 250°F. EPDM rubber is black in color and maintains stability in outdoor environments where weather, UV, and ozone are factors. EPDM is a primary material used in bulk food handling, along with grain storage silos and elevator belts.

FDA Neoprene® Rubber

FDA Neoprene® rubber is produced from FDA-approved ingredients and generally available in an off-white color. It is intended for repeated food exposure, has excellent oil resistance, and is a preferred material for food processing and industrial applications. FDA Neoprene provides reliable service at temperatures ranging from -30°F to 220°F. The material is ideal for specialty applications that demand high performance due to its excellent tensile strength and high tear resistance.

Contact Us for Your Food-Grade Rubber Gasket Needs

Food-grade rubber gaskets are a necessity in any application where the gasket or seal comes in contact with food products during processing and packaging. FDA-approved materials are rigorously tested and strictly monitored to prevent contamination and bacterial build-up.

At ANGOF, we rely on state-of-the-art rubber molding and extruding techniques, along with waterjet cutting, laser cutting, and die-cutting, to tailor our gaskets to your precise specifications. Our experts can identify the best standard food-grade seal or gasket for your application or develop a custom solution using FDA-approved gasket materials.

For more information on FDA-approved rubber solutions or to speak with one of our knowledgeable professionals,pls email your inquiry to info@angoindustry.com.