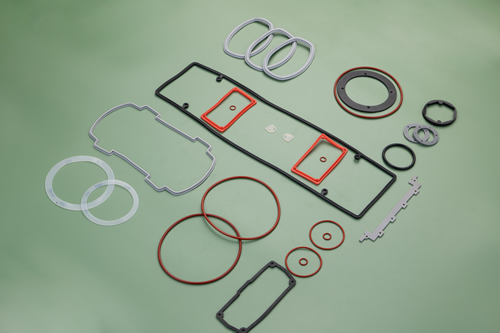

Precision rubber molded products

●Compression molding

●Transfer molding

●Injection molding

●Therforming

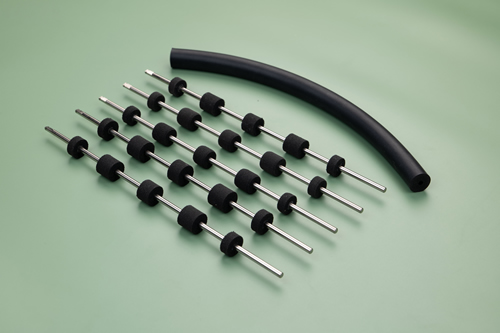

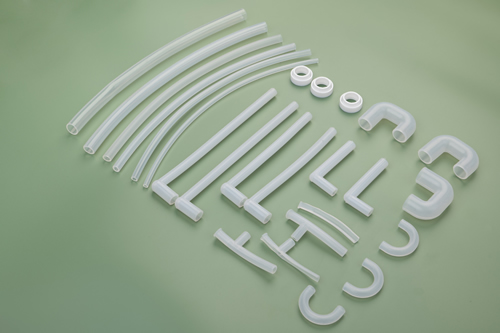

Extrutions profiles

●silicone profiles

●CO-EXTRUTIONS

●EPDM extrutions

●other rubber extrutions

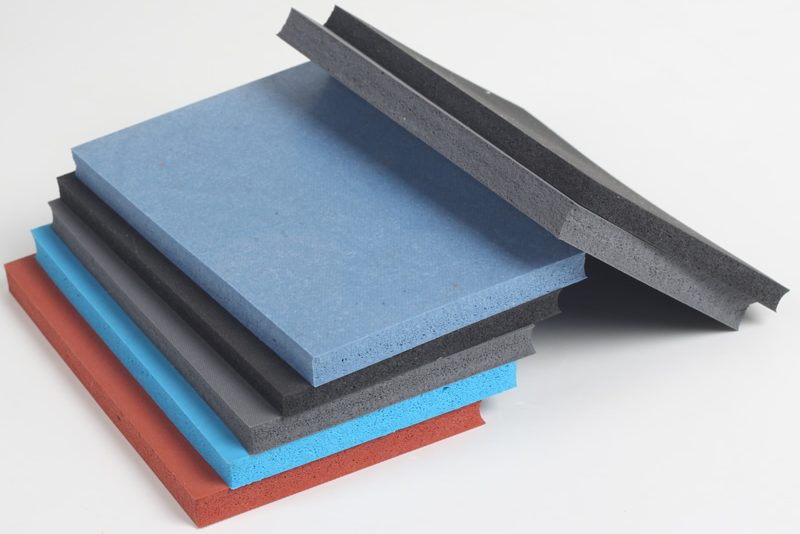

Sponge & foam

●silicone sponge sheet

●HT-800 foam replacement

●Strip cutting

●EPDM/NBR/SBR/CR/PVC sheet

Expert Rubber gasket manufacturing solutions

ANGOF is a leading rubber gasket manufacturer based in Changzhou China,with over three decades of experience in providing high-quality rubber gasekt products to a wide range of industries. We specialize in manufacturing all kinds of rubber extrusions, mouldings, sheeting, gaskets, seals, and rubber matting using both natural and synthetic rubbers (elastomers). We pride ourselves on offering comprehensive support to our customers, including design assistance, material selection and specification, prototyping, and full-scale production.

At ANGOF, we are committed to delivering exceptional rubber gasket products that meet the unique needs of our customers across various industries. Our team of experienced professionals is dedicated to providing top-notch service and support throughout the entire manufacturing process, from design to delivery.

RUBBER DESIGNER

How to customize rubber material based on differenrt properties:

- Rubber can be used over a temperature range of -80°C to +300°C, so it can withstand extremes of weather and outdoor environments indefinitely.

- Rubber can withstand exposure to fuels, oils and chemicals, whilst retaining its excellent properties.

- Rubber can be made flame retardant and self extinguishing, with halogen free and smoke suppressant grades available.

- Rubber can maintain tension and compression forces indefinitely for sealing applications.

- Rubber is conformable, adaptable and can accommodate movement, shock, and thermal changes, operating with tight tolerances and in a variety of surface finishes.

- Rubber can absorb vibration and noise and act as an insulator.

- Rubber can be gas tight and used as a fluid seal or separator.

- Rubber has low thermal conductivity and can be used to reduce heat transfer.

- Rubber has friction properties similar to human skin and is comfortable to grip.

- Rubber can have a clean, smooth surface which can be non-stick and suitable for hygienic applications.

- Rubber is compatible with other engineering materials e.g. metal, plastics and ceramics and can be combined with them in many different ways, including bonding.

- Rubber is available in a wide range of colours.

SOLUTIONS

INDUSTRY

Why Work With US

Designer●Manufacturer

Fast,Supportive,Knowledgeable:

- Our capabilities are boundless, using state of the art machinery and constantly working with laboratories to analyse and formulate new compounds.

- We are committed to the highest quality standards. We succeed in providing superior performance products, at competitive prices, on time.

- Fabricating the mold by our own engineer,ensuring the quality from the begining.

- Working with Fortune 500 companies

- Fast delivery

- FDA,LFGB,REACH Certification available